Personal Protective Equipment (PPE) is an essential aspect of safety in the workplace, especially in environments where hazardous materials and chemicals are present. PPE includes items such as respirators, goggles, hard hats, and protective clothing that are designed to protect workers from injury or illness. However, for PPE to be effective, it must be properly fit tested to ensure that it is the right size and type for the individual worker.

This is where Innovative Engineering Products Pvt. Ltd. (IEPPL) comes in with its expertise, having fit tested thousands of working professionals.

Fit testing is the process of determining the proper fit of a respirator on an individual worker. It is important because a poorly fitting respirator can lead to hazardous exposure to the worker, potentially causing serious injury or illness. For example, if a respirator does not fit properly, harmful particles can enter through the gaps between the respirator and the worker’s face, potentially causing respiratory problems.

The Occupational Safety and Health Administration (OSHA) has set standards for fit testing in the workplace, as outlined in 29 CFR 1910.134. These standards mandate that employers must ensure that their workers are properly fit tested before they are allowed to wear a respirator on the job. Failure to comply with these standards can result in penalties and fines for the employer.

There are two types of fit testing: qualitative and quantitative. Qualitative fit testing is a pass/fail test that uses a test agent, such as a sweet-smelling solution, to check for leaks around the respirator. The worker is asked to perform a series of exercises while wearing the respirator, and if they can smell the test agent, it means that the respirator is not fitting properly.

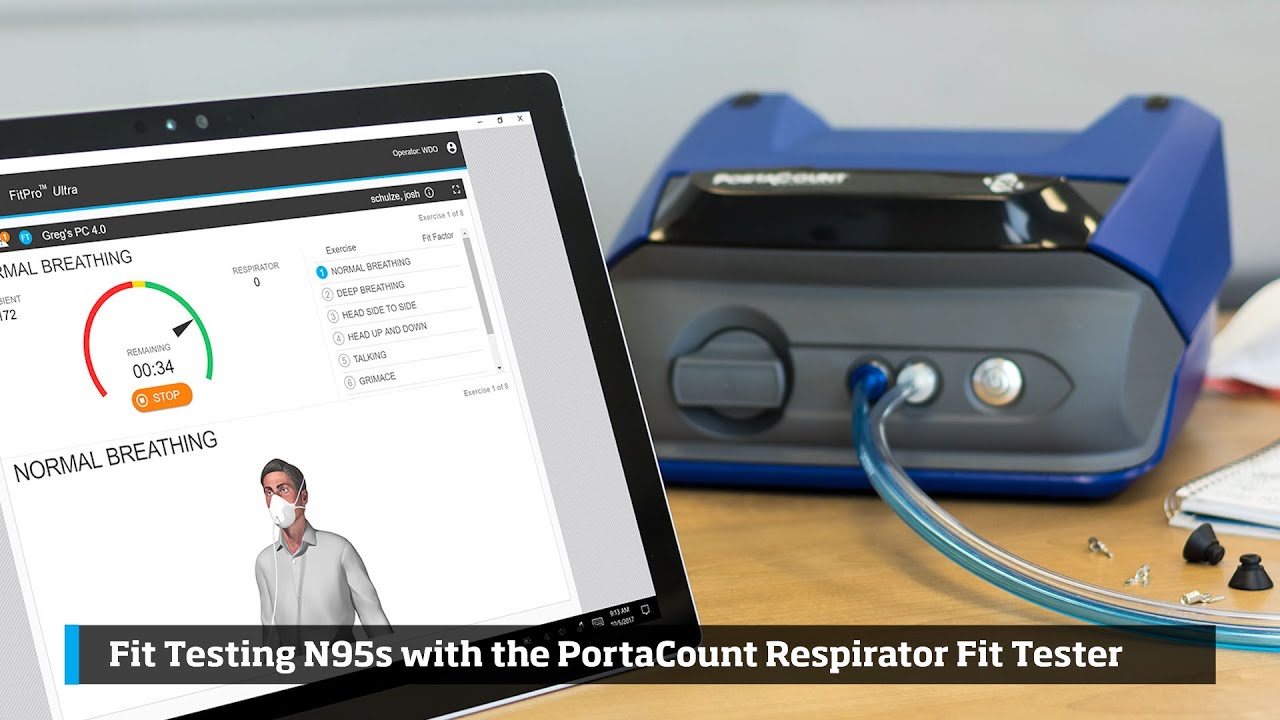

Quantitative fit testing, on the other hand, uses a machine to measure the amount of leakage around the respirator. This method is considered more accurate and reliable than qualitative fit testing. IEPPL uses the state-of-the-art TSI Portacount Fit Testing Machine for quantitative fit testing, which uses a computer to analyze the data and provide a numerical fit factor.

The procedure for quantitative fit testing involves measuring the worker’s face to ensure that the respirator is the right size. The worker is then asked to wear the respirator and perform a series of exercises, such as talking and moving their head, while the machine measures the amount of leakage around the respirator. The worker is then given a fit factor, which is a numerical value that indicates how well the respirator fits. A fit factor of 100 means that the respirator is fitting perfectly, while a lower number indicates that there is more leakage around the respirator.

In conclusion, fit testing is an essential aspect of safety in the workplace, as it ensures that PPE is properly fitted and effective in protecting workers from injury or illness. IEPPL has the expertise to perform both qualitative and quantitative fit testing, using state-of-the-art equipment to ensure accurate and reliable results. It is important for employers to comply with OSHA standards 29 CFR 1910.134, which mandate fit testing, to ensure the safety and well-being of their workers. Properly fit tested PPE can save lives and prevent injuries and illnesses in the workplace, making it a crucial aspect of worker safety.